Certified Chimney Professionals for Your Chimney Brick Spalling Repair

Do you have cracked and crumbling bricks on your chimney? If so, you’re dealing with spalling. This issue occurs because water has entered the porous surface of your concrete, brick, or natural stone. As the moisture causes expansion and contraction, it breaks down, and the surfaces begin peeling, popping out, or flaking off.

Without prompt attention, spalling can compromise the entire structure of your chimney. To prevent these problems, you need to call Guardian Chimney Solutions LLC for chimney brick spalling repair services.

What Causes Chimney Spalling?

Spalling happens for many reasons. The most obvious reason is the constant exposure to heavy rain and melting snow. Water causes bricks and stones to deteriorate and can move into the cracks. After so long, the bricks break down and crumble.

Older bricks may have softened over the years, and they often lack the glazing that protects the surface. Salvaged and repurposed bricks can have the same issue. Gutter leaks and chimney flashing leaks let water into your chimney. This creates more opportunities for spalling.

Chimney Brick Spalling Repair Can Restore the Structure

When you notice spalling chimney bricks, you must act quickly. Hiring the right chimney experts is crucial. Contact Guardian Chimney Solutions LLC. We’ll address the problem and restore your chimney.

Chimney Brick Spalling Repair Restoration

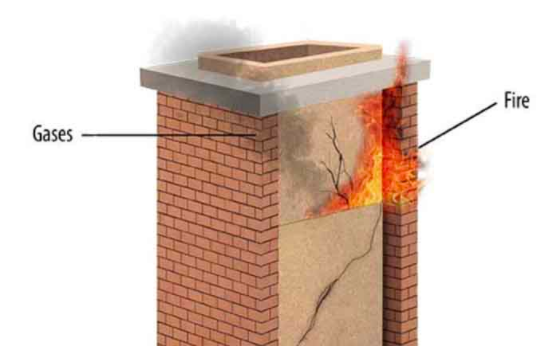

Heat Vapor Escape Causes Spalling

If your chimney has a old flue liner, chances are the seals between the tiles are structurally compromised. A terra-cotta flue liner has a joint seam every two feet as the line rises up the chimney structure. With cracks or gapes in the joints between the flue tiles the venting system is compromised, with out a proper seal the combustion byproducts traveling through the tiles have multiple seepage points. As this vapor seeps out of the tiles it continues its journey up the inside of the cavity, once resting in the top area of the chimney is starts the seeping or freezing process depending on the season seen in the photo fallowing this one.

Moisture Collection & Chimney Repair

One theory is in the frost in the picture shown here. It starts with moisture in the brick and or moisture getting trapped in the chimney chase. As the moisture slowly tries to escape from the brick as it reaches frozen elements, the molecules of water trapped in the brick freeze, they expand and that results in many fracture points threw-out the brick. Over time they deteriorate more and more through the seasons, the loose pieces will starts to break off and fall away from the chimney structure, you will start noticing pieces in the gutter some on the roof.

Chimney Water Pooling in Brinks

When water penetrates the chimney from common entry point such as a crack or chipping to the chimney crown. Once this water has pooled in the core area of the bricks it drains from brick course to brick course, at some point the water will start the seeping process. During the colder seasons its not uncommon for snow to melt during the day and freeze at night. During this freezing process the moisture trapped in the brick from the seeping moisture will expand and cause damage to the masonry materials.

Grind Out Damaged Chimney Area

After locating the damaged areas and marking bricks to be fixed, we use a 5″ diamond blade grinder to grind roughly half way through the bricks to their core area.”As seen in photo” By getting in so deep, it ensures the bonding agent gets a strong bite into the core of the brick structure.

High PSI Air Blower Chimney Repair

This is the second step in our Spalling Brick Refurbishment process. As you can imagine after cutting through mortar with a diamond blade grinder, it leaves a drastic amount of fluffy textured mortar dust. After this process roughly 70% of the dust debris is removed, theirs still a good amount of dust clinging to the open pours created by the diamond blade. So we move on to our next step in the prepping process.

Power Wash Chimney Area

This final step in the prepping process is key, for the fact that neither a brush nor high PSI air will completely remove all leftover dust molecules from the grinding process. This step is commonly missed with many masons. Our outlook on this is every step matters for proper adhesion. When water pressure is applied it completely clears the surface area of the brick joints, by opening up all the surface pours to ensure proper adhesion. A great analogy of skipping this step is like sticking a piece of tape on a dusty floor before using it.